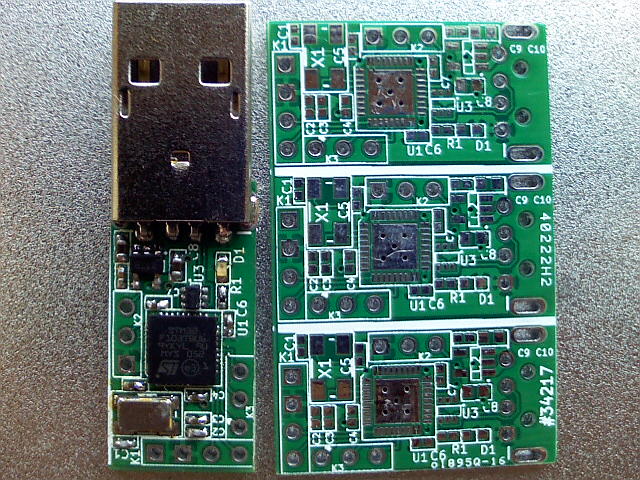

STM32F103TB, which is QFN 36-pin

For the second experimental version of FST-01, I use STM32F103TB, 36-pin QFN chip.

Articles on Surface Mount Soldering

I read (parts of) following articles.

- Extreme Surface Mount Soldering http://www.instructables.com/id/Extreme-Surface-Mount-Soldering/

- Surface Mount Soldering Tutorials http://www.sparkfun.com/tutorials/category/2

- Surface Mount Soldering http://store.curiousinventor.com/guides/Surface_Mount_Soldering

My solution for QFN soldering

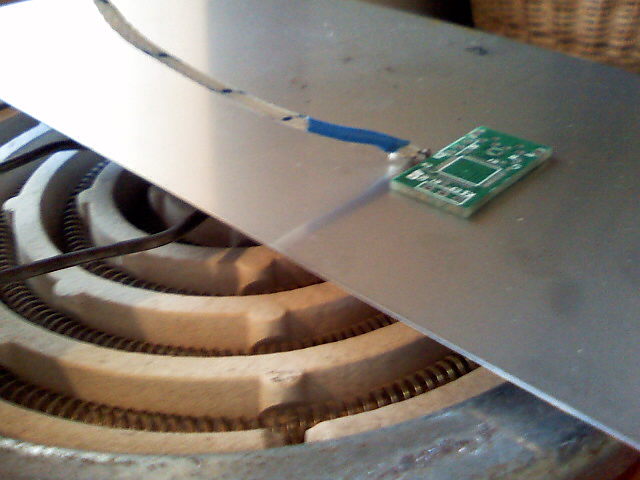

I made my own soldering reflow station. It consists of three parts.

- Electric heater (300W/600W)

- Stainless steel plate (0.5mm (thickness) 100mm x 200mm)

- MS8264 digital multimeter with thermocouple (for temparature measurement)

I put PCB (this is fake, with no parts on top) on the plate and measure temparature and watch reflow process.

Reflow process is simple, turn on, wait, and turn off. To elaborate, it's like following:

- Put PCB on the plate

- Turn on the electric heater (full power, 600W)

- Wait about three minutes for 190 degree (temparature sensor on the plate)

- Watch carefully to see reflow of solder paste

- Turn off the electric heater when it is 210 degree (and solder looks gleam)

Technical points

- Positioning of IC is not that so critical if we compare TQFP hand soldering. With reflow soldering, QFN chip adjusts its position by itself.

- Amount of solder paste should be very small like nothing. It is completely OK not to cover pad by solder paste, but put some (a bit) of paste on the pad. Especially, it is mostly none for the bottom pad of the chip (solder on the PCB pad (solder plating) is almost enough).

- Solder paste is mostly requirement. I tried three times, but I didn't success without solder paste. For four times, I got successes with solder paste (with no failure).

| W/ Solder paste | W/O Solder paste |

|---|---|

| Four success | No success |

| No failure | Three failure |

| recommendation | challenge |

GNU wannabee and Happy Hacking

GNU wannabee and Happy Hacking